Time:2022-04-02

Time:2022-04-02

Author:鑫众

Author:鑫众

Source:News&info

Source:News&info

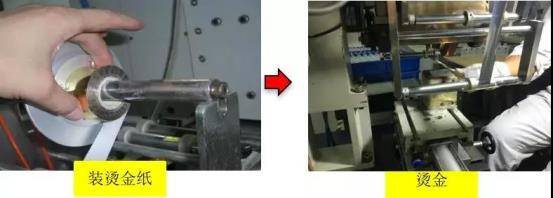

Hot stamping: when the low-temperature screen printing ink is not yet dry, press the product with foil at a high temperature

of 200 degrees. It uses a certain pressure and temperature,Use the template installed on the hot stamping machine to make

the printed matter and hot stamping foil press each other in a short time, meanwhile transfer the metal foil or pigment foil

onto the surface of a printed object being foiled.

For some high-end products, customers will hot stamping the trademark or brand logo on the product. It is mainly gold and silver,

and it can also be used to hot stamping other products. But due to the limitation of raw materials, it is impossible to do color matching.

Main production problems and solutions:

1. Font defect

The font pattern is incomplete, notched and broken. The glass surface is not clean, and there are watermarks, oil, fingerprints, dust

particles and other dirt.Dust or debris sticky at the bottom of the screen plate.The screen is uneven, resulting in not smooth printing.

Solution: avoid touching the bottle with bare hands and dirty gloves, and wipe it with a dry cloth; Before printing, let operator use "electrostatic rod"

to remove dust, and then start silk screen printing. Remove dust and sundries, and the operator checks while printing to ensure that there is no

dust and other dirt on the glass surface, and use a dry cloth to wipe the bottom of the screen frequently; Check the position of the screen every 30

minutes and whether the screws are loose; Adjust the screen level; The technician should pay special attention to the position adjustment of the

screen while changeover.

Xinzhong won second prize of supplier product quality in 2nd Langjiu Estate Triple Pin Festival

Xinzhong participated in China Plas 2021

What is UV ink and its application

Application of heat transfer printing on glass wine bottle

Application of silkscreen printing technology in wine bottle

20 years of automatic machinery in the field of curved screen printing and bronzing Manufacturing experience

0755-26984403 15013885272

0755-26984403 15013885272

Email:baithol@163.com

Email:baithol@163.com

Address:Bldg. 3 Daerxun Ind. Area PingXin North 29# Pinghu Town Longgang Shenzhen

Address:Bldg. 3 Daerxun Ind. Area PingXin North 29# Pinghu Town Longgang Shenzhen

Official WeChat account

Official WeChat account

Official WeChat account

Official WeChat account